Welcome

Since 1970 LOUISE Engineering Ltd. is the contact for clients of the energy industry, e.g. power industry and waste handling, the chemical industry, the cement industry and metallurgical industry. Projects with non-free flowing bulk materials for BDM, RDM, SDM, CCV and TRU were realized in this time. The company, with its knowledgeable staff, has wide experience in bulk handling technology and silo discharge systems, as well as in steel constructions. All bulk material handling systems are designed and constructed to meet the specific requirements imposed by the materials concerned.

If necessary we test problematic bulk materials in the laboratory, including the use of a Jenike type shear cell. The resulting data will be analysed and assessed by means of special computer programs.

Product Range

The company specializes in equipment designed for the conveying, storing and discharge of bulk materials.

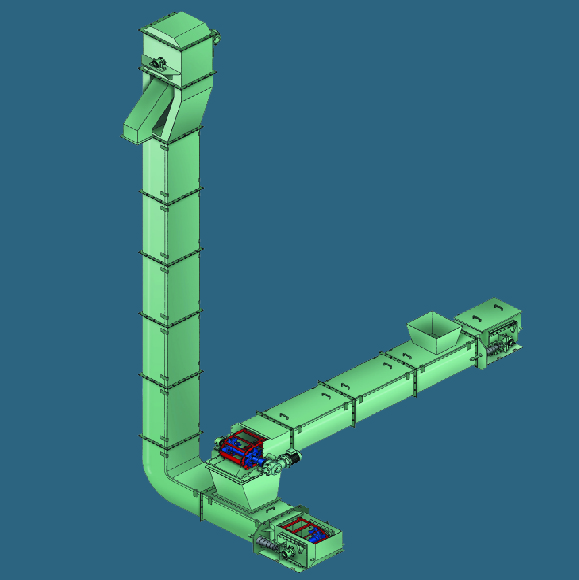

CC

Chain Conveyor is designed of heavy duty dust, gas tight and explosion-proof material and can be used for most relatable and durable systems available in any industry. Sticky, hot, abrasive materials such as synthetic gypsum, sludge and clinker are easily conveyed up to 2000 t/h on single or double strand chain. Download

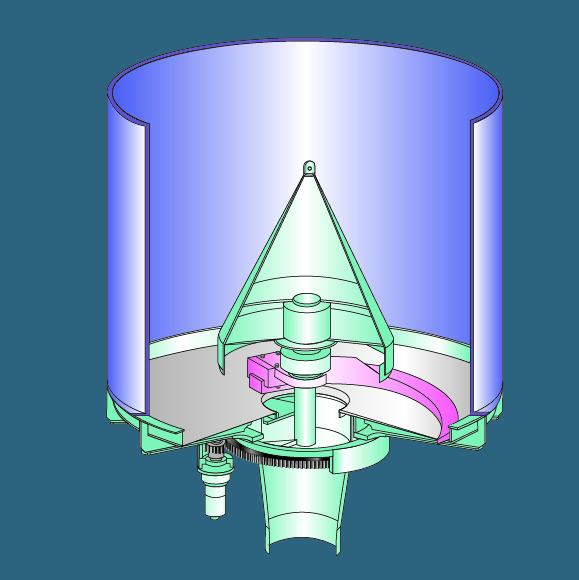

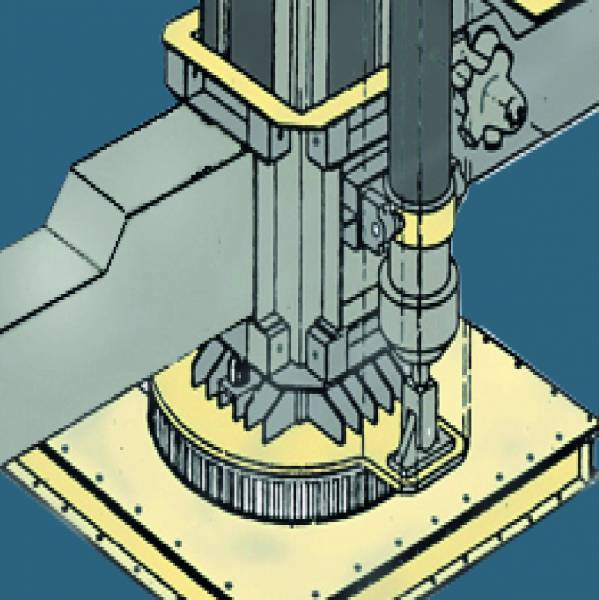

SDM

SDM Silo Discharge Mashine is available in diameters from 1.5 to 6 meters for flow rates up to 1000 t/h. With material testing and a special design it is possible to achieve maximum storage and mass flow discharge from the silo.

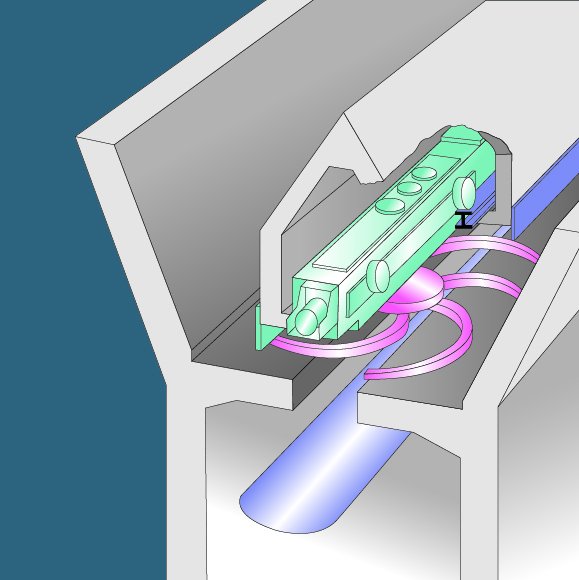

BDM

BDM Bunker Discharge Machine is used for a dosed pull-off of flowing bulk material. The pull-off takes place in the silo and bunker machines and beneath bulk material halls. The stored bulk material, limestone, gypsum, clinker, coke and coal is pulled off by the BDM continuously. Download

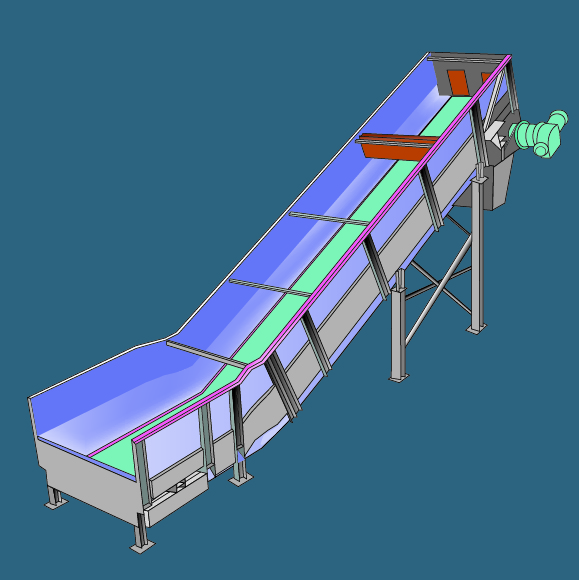

TRU

TRU Truck Reception Unit is designed to speed the receiving of bulk materials into a processing facility without the need for costly excavation, civil work, or underground pits. Commonly used to unload bulk materials from dumping trucks or fed by front end loaders, the TRU will then feed your bulk material to your process at a specified rate. Download

RDM

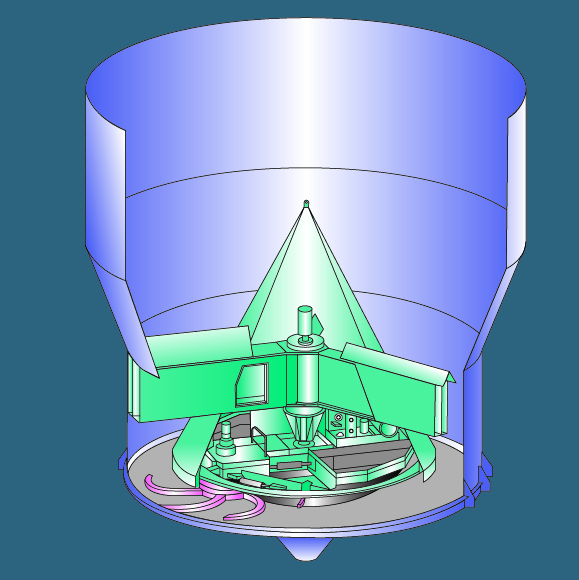

RDM Rotary Discharge Mashine can be used for largest discharge systems with material storage capacities up to 10.000 t and diameters from 5 to 12 meters. It is recommended in power, cement, wall board, waste handling and other industries, where non free flowing material is used.

DM

Deslagging Machine can be used for the removal of the slag during the steel production and the aluminium production in the metallurgical industry.

Deslagging Machine can be used for the removal of the slag during the steel production and the aluminium production in the metallurgical industry.